-

GST NO. : 27ABVPW3846L1ZJ

-

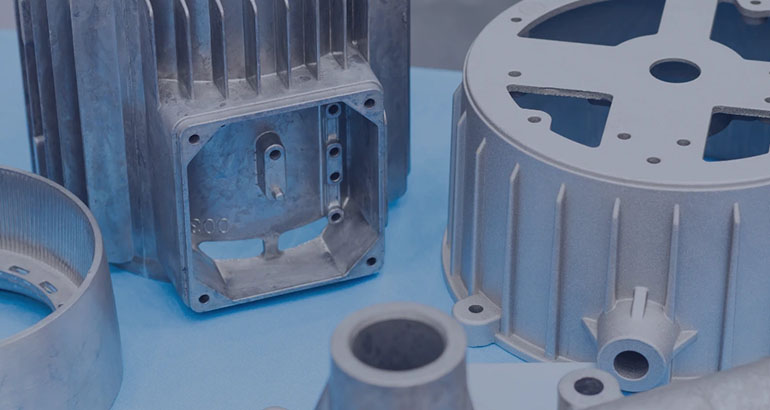

Non Ferrous Die Casting

Non Ferrous Die Casting Manufacturers, Suppliers, Dealers, Exporters in Chakan

Non Ferrous Die Casting in Chakan

Shreeniwas Casttech Industries is the leading Non Ferrous Die Casting manufacturers, suppliers, dealers, exporters in Chakan. With a commitment to precision and innovation, we specialize in crafting high-quality components from non ferrous alloys. Our state-of-the-art facilities and skilled team ensure superior casting solutions for diverse industries.

From concept to completion, we prioritize quality, efficiency, and client satisfaction. Explore the advantages of non ferrous die casting with us — where expertise meets excellence.

What is Non Ferrous Die Casting?

Non ferrous die casting is a sophisticated metal casting process primarily employed for alloys that do not contain iron, such as aluminum, zinc, copper, and magnesium. This method involves injecting molten metal into a pre-designed mold under high pressure, resulting in the production of intricate and high-precision components.

Non ferrous die casting is characterized by its ability to create complex shapes with high dimensional accuracy, making it ideal for components with intricate details. The process ensures excellent surface finishes, reducing the need for additional machining. Alloys like aluminum and zinc are commonly used due to their lightweight nature and superior casting properties.

Advantages

Precision and Detail: Non ferrous die casting enables the production of intricate and detailed components with tight tolerances, meeting high-quality standards.

Cost-Efficiency: The process is cost-effective for large-scale production, as it allows for high-speed production cycles and minimal post-casting machining.

Weight Reduction: Aluminum and magnesium alloys, frequently used in non ferrous die casting, offer excellent strength-to-weight ratios, contributing to lightweight and durable components.

Corrosion Resistance: Non ferrous alloys are inherently corrosion-resistant, making the resulting components suitable for various applications, especially in industries where exposure to harsh environments is common.

Industrial Uses

Automotive Industry: Non ferrous die casting is widely employed in the automotive sector for manufacturing engine components, transmission parts, and structural elements due to its lightweight properties and cost-effectiveness.

Electronics: The process is utilized in the production of electronic components, including housings, heat sinks, and connectors, owing to its ability to create intricate shapes and maintain excellent thermal conductivity.

Aerospace: The aerospace industry benefits from non ferrous die casting for manufacturing lightweight yet strong components like aircraft parts and structural elements, contributing to fuel efficiency.

Consumer Goods: Non ferrous die casting is integral to the production of various consumer goods such as appliances, sporting equipment, and decorative items, ensuring both functionality and aesthetic appeal.

Quality Services provider

Need Our services?

-

Our Products Range