-

GST NO. : 27ABVPW3846L1ZJ

-

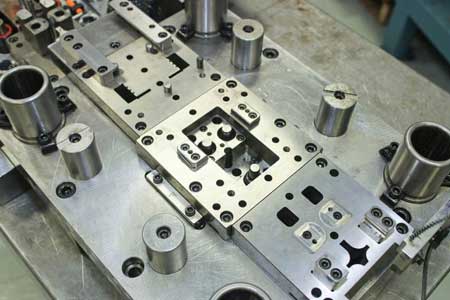

Die Making

Die Making

Here's an overview of the die making process:

- 1. Design:

-

- The die-making process begins with the design phase. Engineers and designers create detailed drawings and specifications for the die based on the product or part requirements.

- 2. Material Selection:

-

- The material used for the die depends on the application and the type of material being processed. Common die materials include tool steel, carbide, and various alloys chosen for their hardness, durability, and wear resistance.

- 3. Machining or Tooling:

-

- Once the design is finalized, the die is created through machining or tooling processes. CNC (Computer Numerical Control) machining is often used to precisely shape the die components according to the design specifications.

- 4. Heat Treatment:

-

- In many cases, the die undergoes a heat treatment process to improve its hardness and toughness. This is important for ensuring the die can withstand the repeated stresses and pressures encountered during the manufacturing process.

- 5. Assembly:

-

- The various components of the die, such as the punch and die block, are assembled and securely fastened together. The assembly must be precise to ensure the die functions as intended.

- 6. Testing and Adjustments:

-

- The completed die undergoes testing to ensure it meets quality standards. Adjustments may be made to fine-tune the die's performance.

- 7. Installation:

-

- The die is used in the production process to create multiple copies of the desired product or part. This could involve cutting, forming, or molding the material.

- 8. Production:

-

- The die is used in the production process to create multiple copies of the desired product or part. This could involve cutting, forming, or molding the material.

Die making is a critical step in various manufacturing processes and is often employed in industries such as automotive, aerospace, electronics, and consumer goods. Dies can be designed for a wide range of applications, including sheet metal stamping, plastic injection molding, extrusion, and more. The precision and quality of the die directly impact the quality and consistency of the final manufactured products.

Quality Services provider

Need Our services?

-

Our Products Range